Product Categories

Related products

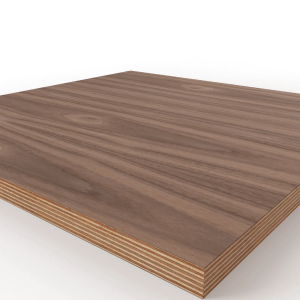

What is Red Oak Plywood ?

Red Oak plywood is a high-end plywood made from Quercus rubra, a North American red oak wood, and belongs to the hardwood decorative board category. Red oak is widely used in furniture, flooring, and architectural decoration in Europe and America due to its rough wood grain, high strength, and good durability. Red Oak plywood is a classic choice of American retro and industrial style, suitable for furniture that pursues rough wood grain and a sense of heavy weight; High hardness load-bearing structures are required (such as stairs, workbenches); A project with a budget lower than that of black walnut/white oak, but still requiring hardwood performance. If you prefer finer textures or need moisture resistance, you can consider white oak plywood; If the budget is limited, rubber wood plywood is a flat alternative option.

characteristic

1. Material characteristics

Color and texture:

The heartwood is light brownish red to pinkish brown in color, with obvious open ductal texture (visible “pores” to the naked eye), and the texture is rough and three-dimensional. After oxidation, it will gradually darken and present a richer amber color tone.

Physical performance:

High hardness (approximately 1290 lbf Jenca hardness), better wear resistance than pine and rubberwood, and close to white oak.

Moderate stability (requires drying treatment to avoid cracking), suitable for indoor environments with stable temperature and humidity.

2. Processing performance

Easy to polish and paint, but open conduits require fillers (such as sawdust and glue) to achieve a smooth surface.

It is easy to crack when nailing, it is recommended to pre drill holes.

3. Environmental friendliness

Red oak is a natural wood, and if the glue reaches E0/E1 level (such as CARB P2 certification), it meets environmental standards.

| Red Oak Plywood vs Regular Plywood | ||||

| Characteristic | Red Oak Plywood | White oak Plywood | Pine Plywood | Rubber Wood Plywood |

| hardness | High (1290 lbf) | Higher (1360 lbf) | Low (400-500 lbf) | Medium (850-950 lbf) |

| texture | Rough, open conduit | Delicate, closed catheter | Obvious scar formation | Uniform and scar free |

| moisture resistance |

⭐⭐⭐

(To be sealed)

|

⭐⭐⭐⭐

(White oak with tannin moisture resistance)

|

⭐⭐

(Easy to deform)

|

⭐⭐⭐

(requires anti-corrosion treatment)

|

priceHigh end (300-600 yuan/sheet)Higher (400-800 yuan/sheet)Low (60-120 yuan/sheet)Medium (80-180 yuan/sheet)Applicable styleAmerican style, industrial styleJapanese, NordicRural styleModern Simplicity

Usage

High end furniture

American/industrial style bookshelf, dining table, bar counter (highlighting rough wood grain).

Interior decoration

Solid wood flooring, stair treads, vintage wall panels (durable and visually impactful).

building structure

Door frames, beams and columns (utilizing their high load-bearing capacity).

Wine barrels and utensils

Wine barrel (requiring special treatment), tool handle (anti slip and wear-resistant).

Advantages and limitations of Red Oak plywood

✅ advantage

Unique texture: The open conduit brings a strong sense of three dimensionality, suitable for retro or industrial design.

High durability: Hardness close to white oak, suitable for high-frequency use of furniture (such as dining tables).

Strong dyeing ability: easy to age or dye dark colors (such as imitating the effect of black walnut).

❌ limitation

Sealing treatment required: The conduit is prone to dirt accumulation and needs to be filled or regularly coated with wood wax oil for maintenance.

High price: only lower than top hardwood such as black walnut and white oak.

Stability is average: it may crack when there is a sudden change in temperature and humidity, and is not suitable for humid environments such as bathrooms.

Purchase suggestions

Level:

AA grade: Double sided red oak leather, flawless, suitable for visible areas such as tabletops.

AB grade: Red oak leather on the front, ordinary wood leather on the back, with higher cost-effectiveness.

Check the substrate:

Choose birch or poplar wood core to avoid the influence of cork substrate (such as pine wood) on strength.

Surface treatment:

Choose pre filled conduit boards or fill them with epoxy resin yourself.

Contact us for free sample

- WhatsApp: +8616506393789

- plywood@yiwanjiawood.com

- Room 1008, Block A, Phase I, Yigao Shanghai Street, Lanshan District, Linyi City, Shandong Province