Product Categories

Related products

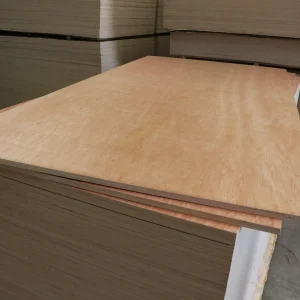

| Name | Melamine Plywood |

| Size | 1220*2440mm |

| Thickness | 2mm,3mm,4mm,5mm,9mm,12mm,15mm,18,21mm,etc |

| Core material | Poplar ,Eucalyptus ,Birch ,Combi,MDF Chipboard OSB etc |

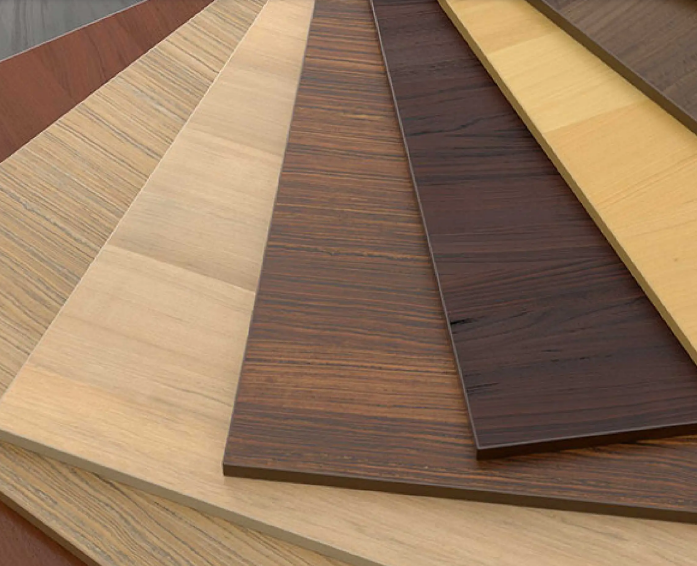

| Face | Melamine paper,matt, high glossy |

| Color | Solid color, wood grain, marble grain, cloth grain, etc.(We can produce the same color according to customer’s samples) |

| Environmental grade | E0,E1,E2 |

| Application | Home decoration, panel furniture, cabinet wardrobe, bathroom cabinet and other fields. |

What is melamine Plywood ?

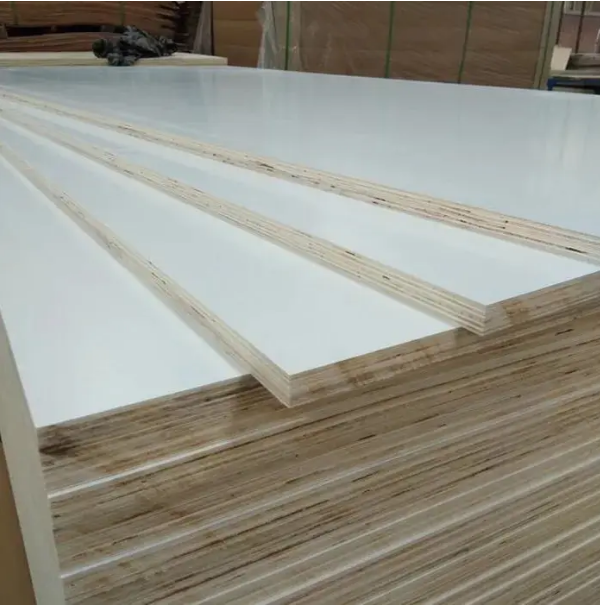

Melamine Plywood is a type of plywood with a surface coated with melamine impregnated paper. The core substrate is usually ordinary plywood (such as poplar wood, pine wood), particleboard, or density board. The triamine film is bonded to the substrate through high temperature and high pressure to form a wear-resistant and moisture-proof decorative board.

Triamine plywood is a low-cost and highly practical decorative board, suitable for: furniture customization with limited budget; Commercial projects that require quick installation; Wear resistant and easy to clean daily use scenarios. If pursuing natural texture or high-end environmental protection, it is recommended to choose natural wood veneer plywood (such as EV board); If the budget is extremely low and only temporary use is needed, ordinary bare plywood is more economical.

characteristic

1. Surface characteristics

Strong wear resistance: The triamine film has high hardness and scratch resistance, making it suitable for high-frequency use scenarios such as desktops and cabinet doors.

Good moisture resistance: Compared with ordinary plywood, the triamine surface can block water vapor to a certain extent (but the substrate is still afraid of water, and edge sealing is the key).

No need for painting: The surface has been treated and no additional coating is required. It can be directly cut and sealed for use.

Rich colors: can imitate wood grain, stone grain, solid color, and even metallic texture, meeting diverse design needs.

2. Substrate selection

Plywood base (such as poplar/pine core): with high strength, suitable for load-bearing furniture.

MDF/particleboard base: Good flatness, but poor moisture resistance, suitable for dry environments.

3. Environmental friendliness

Depending on the substrate and adhesive, high-quality triamine boards can reach E0 level (formaldehyde emission ≤ 0.05mg/m ³), while inferior products may contain formaldehyde (requiring CARB, F4 star certification, etc.).

| Melamine Plywood vs Regular Plywood | ||

| Characteristic | Triamine plywood | Regular plywood |

| wear resistance |

⭐⭐⭐⭐⭐

(Strongest)

|

⭐⭐

(Easy to scratch)

|

| moisture resistance |

⭐⭐⭐

(Surface layer moisture-proof, substrate afraid of water)

|

⭐⭐

(Easy to expand)

|

| Appearance selection | Rich (imitating wood grain, stone grain, etc.) | Single (dependent on post-processing) |

| price | Medium to low (80-200 yuan/sheet) | Low (50~150 yuan/sheet) |

| environmentally | Depending on the substrate (E0~E1 grade) | May contain formaldehyde (E2 grade should be avoided) |

Usage

1 panel furniture

Cabinets, wardrobes, bookcases, cabinets, and door panels (cost-effective and easy to clean).

2 Commercial spaces

Office partitions, store display cabinets, hotel furniture (durable and versatile).

3 Home Decoration

Wall protection panels, countertops, and simple partitions (no need for painting, fast construction).

4 Laboratories/Hospitals

Antibacterial triamine board is used for operating consoles and medicine cabinets (requiring special treatment).

Advantages and Limitation of melamine plywood

✅ advantage

Low cost: cheaper than solid wood veneer plywood, suitable for bulk procurement.

Ready to use: eliminates the need for painting process and shortens the construction period.

Easy to maintain: Stains can be wiped clean immediately, suitable for daily household use.

❌ disadvantage

High requirements for edge sealing: If the edge sealing is not strict, the substrate will still expand when it comes into contact with water.

Texture is more plastic like: Imitation wood grain is not as realistic as natural wood veneer, and should be used with caution in high-end projects.

Non repairable: The surface cannot be polished or repaired after being scratched, and can only be replaced.

Purchase suggestions

Substrate priority:

Choose a moisture-proof plywood base (such as eucalyptus core+WBP adhesive) for damp environments, and avoid using a density board base.

Check the edge banding:

High quality products use PVC or ABS edge banding without adhesive seams.

Environmental certification:

Identify E0 or F4 star rating (daily standard, formaldehyde emission ≤ 0.03mg/m ³).

Contact us for free sample

- WhatsApp: +8616506393789

- plywood@yiwanjiawood.com

- Room 1008, Block A, Phase I, Yigao Shanghai Street, Lanshan District, Linyi City, Shandong Province