Product Categories

Related products

| Name | Birch plywood |

| Size | 1220x2440mm,1250x3000mm, or as Customized |

| Thickness | 2.7~30mm |

| MOQ | 20GP |

| Glue | WBP phenolic, WBP melamine |

| Face/Back | Full birch |

| Core Material | Birch,Eucalyptus, Poplar,Combi core or as request |

| Certification | CE,EUTR,CARB,EPA |

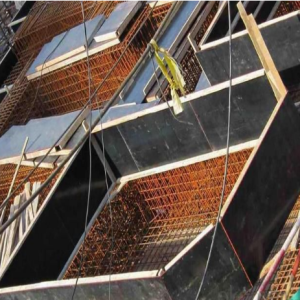

| Usage | Furniture, Laser Die Cutting, Toy, Loud Speaker, Construction, Flooring,etc |

What is Birch Plywood ?

Birch plywood is a multi-layer laminated board made mainly from birch wood. It is made by stacking birch veneer (thin wood sheets) in a staggered manner according to the grain direction and bonding them together under high temperature and high pressure. Its characteristics are smooth surface, clear texture, high strength and good stability, making it a mid to high end product in plywood. With its strength and aesthetics, it is widely used in fields that require high quality, especially suitable for scenarios that require a balance between functionality and design.

feature

Uniform material: Birch wood has delicate texture, light color (slightly white or light yellow), straight and beautiful texture, suitable for fine processing.

High strength: The multi-layered staggered structure makes the bending and compression resistance of the board superior to ordinary wood.

Good stability: not easily deformed or cracked, moisture resistant (especially for models that have undergone waterproof treatment).

Easy to process: It can be sawed, drilled, veneered, and painted, suitable for various process requirements.

| Birch Plywood vs Regular Plywood | ||

| Characteristic | Birch plywood | Regular plywood (such as poplar/pine) |

| Density/Strength | tall | low |

| Texture Aesthetics | Excellent (suitable for bare use) | Generally (often requires skin covering) |

| price | higher | Lower |

| Moisture resistance |

Medium

(requires waterproof treatment)

|

Low

(pine slightly better than poplar)

|

| Applicable scenarios | High end furniture and decoration | Packaging, building templates, ordinary furniture |

Usage

1 Furniture manufacturing

Used for making mid to high end furniture (such as wardrobes, cabinets, tables, chairs, etc.), especially suitable for styles that require surface coating or pasting.

2 Interior Decoration

Wall and ceiling lining, or as a base layer for flooring (requiring surface layer materials).

Customized partitions, display cabinets, store shelves, etc.

3 Packaging and Transportation

Export packaging boxes, pallets, etc. are designed to protect valuable items due to their high strength and high energy.

4 Creative DIY and Modeling

Handmade production and model construction (such as sand tables and stage sets), due to their ease of cutting and smooth surface.

5 Other industrial uses

Instrument components (such as guitar backboards), toys, car and vessel interiors, etc.

Advantages vs. other plywood

Compared to poplar plywood: birch has a higher density and is more wear-resistant, making it suitable for fine furniture.

Compared to pine plywood: Birch wood has a more beautiful texture, but is usually more expensive.

Note

When choosing, attention should be paid to the environmental level (such as E0 and E1 standards) and the type of adhesive (recommended for indoor use with low formaldehyde emissions).

Outdoor use requires selecting a waterproof model (such as “Marine Plywood” grade).