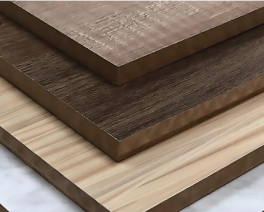

MDF

MDF (Medium Density Fiberboard) is an artificial board made by mixing wood fibers (or plant fibers) with synthetic resins (such as urea formaldehyde glue) and pressing them under high temperature and high pressure. Its density is usually between 600-800 kg/m ³, between particleboard (low-density) and high-density fiberboard (HDF).

| Name | MDF |

|---|---|

| Size | 1220x2440mm,1250x2500mm,1250x3000mm,1525x1525mm 1525x3050mm or as Customized |

| Thickness | 2~30mm |

| Face/Back | Pure,Melamine,HPL,PET, |

| Core Material | MDF,HDMR,MR,Fire-proof MDF,HDF |

| Glue | E0,E1,E2 |

| Moisture Content | 7%-16% |

| MOQ | 1*40HQ |

| Density | 650-900kg/m3 |

| Usage | deck of boat,outdoors |

Characteristic

1. Uniform material and smooth surface

Made by pressing fine wood fibers, without the knots or texture differences of natural wood, suitable for fine processing such as carving, pasting, and painting.

High surface flatness, commonly used for furniture, door panels, etc. that require smooth finishes.

2. Easy to process, strong plasticity

It can be cut, drilled, and carved with ordinary woodworking tools, and is not prone to edge breakage, suitable for complex shapes such as European lines and hollow designs.

Can be coated with PVC film, solid wood veneer, or directly sprayed with paint, with strong decorative properties.

3. Good stability, not easily deformed

The fiber structure is uniform, less affected by temperature and humidity, and less prone to cracking or warping than natural wood (but still requires moisture-proof treatment in humid environments).

4. Environmental friendliness (depending on the adhesive)

Ordinary MDF uses urea formaldehyde adhesive, which may release formaldehyde (choosing E0/E1 environmental standards can reduce risks).

Some high-end products use MDI glue (formaldehyde free glue), which is more environmentally friendly.

5. Moderate price

Cheaper than solid wooden boards, slightly more expensive than particleboard, with high cost-effectiveness, suitable for large-scale production.

6. Disadvantages

Not waterproof: prone to swelling when in contact with water, requiring special treatment (such as moisture-proof MDF or surface edge sealing).

Weak nail grip: The screw is prone to loosening after repeated disassembly. It is recommended to use pre drilled holes or specialized fasteners.

Heavy weight: high density, more labor-intensive to transport and install than solid wood.

| MDF vs Other Booard | ||||

|---|---|---|---|---|

| characteristic | MDF | Particle board | plywood | Solid wood board |

| material | Wood fiber+glue | Wood chips+glue | Cross laminated thin wood sheets | natural wood |

| Surface smoothness | Aurora Slide | Rougher | Smooth (depending on the finish) | Has natural texture |

| waterproofness | Poor (requires moisture-proof treatment) | differ from | Medium (waterproof treatment) | Depending on the type of wood |

| nail-holding power | weak | weak | strong | strong |

| price | medium | minimum | higher | highest |

Usage

Furniture manufacturing: cabinet doors, drawer panels, TV background walls (due to easy carving and shaping).

Interior decoration: skirting board, door frame, wall panel, ceiling.

Customized craftsmanship: photo frames, toys, models (easy to cut and polish).

Audio equipment: speaker enclosure (with uniform density to reduce resonance).

Note

Avoid using in damp environments (such as bathrooms, outdoors) unless choosing moisture-proof MDF (green label) or waterproof MDF (HMR grade).

Wear a mask during cutting to prevent inhaling wood fiber dust.

Edge sealing treatment can extend the service life and reduce formaldehyde emissions.

If higher strength or waterproof performance is required, HDF (high-density fiberboard) or plywood can be considered.

Type

Moisture-resisitance MDF

MDF

MDF with Melamine paper

LDF

HDF

Fire-proof MDF

Contact us for free sample

- WhatsApp: +8616506393789

- plywood@yiwanjiawood.com

- Room A-1008,Building 1,Yigao Shanghai Street Liuqing Sub-district Lanshan Distrct Linyi City ,Shandong Province, China