Film Faced Plywood

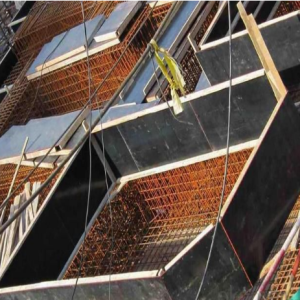

Film Faced Plywood is a high-strength plywood with a surface covered with waterproof and wear-resistant film, designed specifically for concrete pouring construction, and is one of the mainstream materials for construction formwork. Its core features are waterproof, corrosion-resistant, and reusable, widely used in construction projects.Film Faced Plywood has become the preferred choice for modern building templates due to its waterproofing, high strength, and reusability, especially for concrete projects that require a balance between cost and efficiency. Proper selection and maintenance can significantly improve construction quality and reduce losses.

| Name | Film Faced Plywood |

|---|---|

| Size | 1220x2440mm,1250x2500mm,1250x3000mm,1525x1525mm 1525x3050mm or as Customized |

| Thickness | 2~30mm |

| Face/Back | Birch,Pine,Okoume,Poplar,Melamine,White Recon,Red Oak,White Oak,Walnut,Cherry,Maple,Teak,UV ,PET According to your needs |

| Core Material | Birch,Eucalyptus,Poplar,Combi core,Rubber ,Plaulownia, or as request |

| Grade | According to the face specis |

| Glue | Phenolic,E1,E0 |

| MOQ | 1*40HQ |

| Moisture Content | Below 14% |

| Density | 550-860kg/m3 |

| Usage | Furniture,Laser Die Cutting,Toy,Loud Speaker,Construction,Flooring,etc |

Characteristic

1. Surface film coating

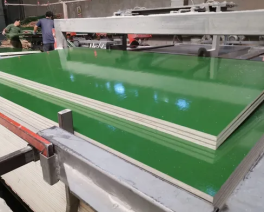

Double sided coverage of phenolic resin film (Brown/Black/Green/Red Film), smooth and waterproof, with a smooth concrete surface after demolding.

The film is acid and alkali resistant, and UV resistant (suitable for outdoor construction).

2. Substrate structure

The core layer is made of hardwood (such as poplar, eucalyptus, pine) or composite wood, with multiple layers of cross bonding and high bending strength.

The adhesive is usually waterproof phenolic glue (WBP, compliant with EN 314-2 standard).

durability

Can be reused 10-30 times (ordinary wooden formwork only 2-5 times), significantly reducing construction costs.

| Film Faced Plywood vs Formwork | |||

|---|---|---|---|

| characteristic | Film Faced Plywood | Ordinary wooden formwork | Steel formwork |

| durability | 10-30 times | 2-5 times | 100+times |

| cost | medium | low | tall |

| Concrete surface | smooth | Need for secondary processing | Smooth but easy to stick mold |

| Applicable scenarios | Small and medium-sized buildings, bridges | Temporary Works | Large repetitive structures |

Usage

1. Concrete pouring construction

Wall/column formwork: supporting concrete shaping, easy demolding of laminated surface, reducing residue.

Floor/beam formwork: High strength load-bearing to avoid deformation during pouring.

Bridge/tunnel engineering: resistant to moisture and long-term loads, suitable for large-scale infrastructure construction.

2. Special building requirements

Clear faced concrete: Covering film provides a smooth surface, directly presenting decorative concrete effects.

Curved structure: Some laminated boards can be bent to accommodate irregular designs.

3. Other industrial uses

Temporary flooring/workbench: pressure resistant and moisture-proof, used for construction sites or factories.

Packaging box/container pad: high-strength moisture-proof, replacing ordinary plywood.

Purchase suggestions

Select level according to engineering requirements:

Ordinary engineering: 12-18mm, brown film, high cost-effectiveness.

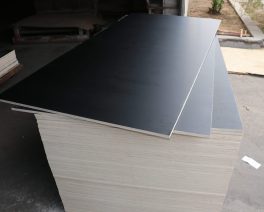

High strength engineering: 18-21mm, black film, stronger weather resistance.

Quality inspection:

Observe whether the film coating is uniform without bubbles and the edges are not cracked.

The core layer has no voids and the layers are tightly stacked (listen for a dull sound when tapping).

Types

Black Film Faced Plywood

Brown Film Faced Plywood

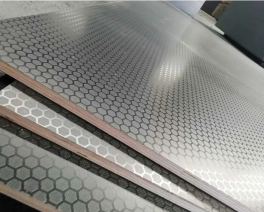

Anti-slip Fim Faced Plywood

Green Plastic Film Faced Plywood

Contact us for free sample

- WhatsApp: +8616506393789

- plywood@yiwanjiawood.com

- Room A-1008,Building 1,Yigao Shanghai Street Liuqing Sub-district Lanshan Distrct Linyi City ,Shandong Province, China