Chipboard

Chipboard (commonly known as “particleboard” or “particle board” in Chinese) is a type of artificial board made by mixing wood chips (such as sawdust and shavings) with adhesive and pressing them under high temperature and high pressure. It is widely used in furniture manufacturing, architectural decoration, packaging and other fields. Chipboard is an economical and practical multifunctional board suitable for cost sensitive and batch processing scenarios, but specific types such as moisture-proof and environmentally friendly need to be selected according to the purpose.

| Name | Chipboard |

|---|---|

| Size | 1220x2440mm,1250x2500mm,1250x3000mm,1525x1525mm 1525x3050mm or as Customized |

| Thickness | 2~30mm |

| Face/Back | Pure,Melamine,HPL,PET, |

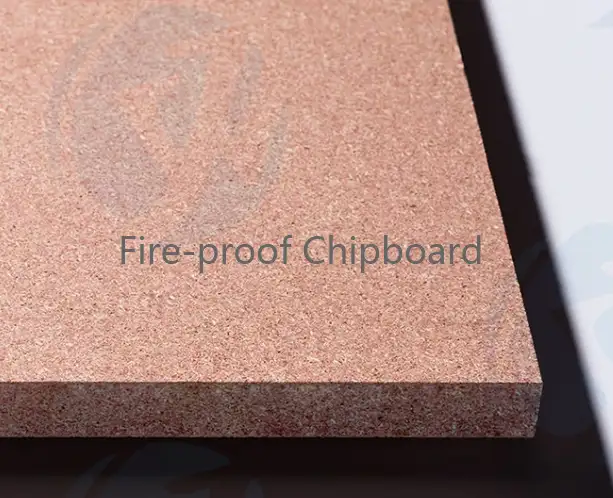

| Core Material | Chipboard ,MR Chipoard,Fire-proof Chipboard |

| Grade | E0,E1,E2 |

| Moisture Content | 7%-16% |

| MOQ | 1*40HQ |

| Density | 650-900kg/m3 |

| Usage | Furniture,Laser Die Cutting,Toy,Loud Speaker,Construction,Flooring,outdoors ,House,etc |

characteristic:

1. Basic definition and production process

Composition: Made from wood processing residues (such as sawdust, sawdust) or recycled wood, bonded with adhesives (such as urea formaldehyde resin, phenolic resin).

Production process: including steps such as sawdust classification, drying, gluing, paving, hot pressing, etc. Some high-end products will undergo surface lamination or veneer treatment.

2. Main features

(1) Physical performance

Strength and stability: Multi layer structures (such as three or five layers) are designed to enhance bending and compression resistance, but overall strength is lower than plywood or solid wood.

Density and weight: The density range is wide (280-800 kg/m ³), low-density boards are lighter but have lower strength, while high-density boards are more durable.

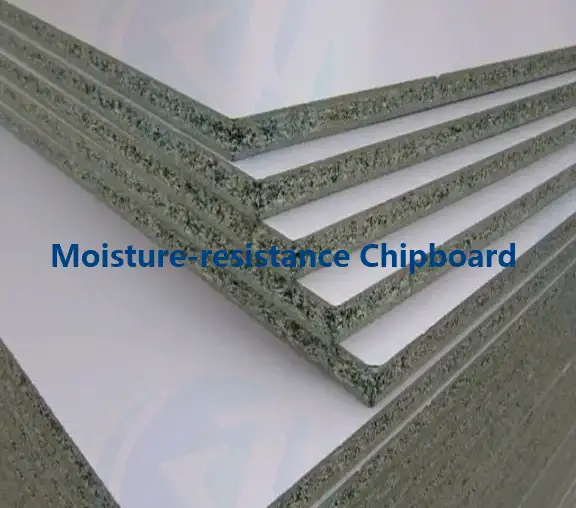

Moisture resistance: Ordinary particleboard is prone to moisture expansion, but adding paraffin or moisture-proof adhesive can improve water resistance (such as “moisture-proof particleboard”) 96.

(2) Processing and Application

Easy to process: capable of sawing, drilling, and edge sealing, suitable for mechanized production, commonly used in furniture cabinets, door cores, partitions, etc.

Surface decorative: It can be improved in appearance by imitating the texture of solid wood through veneers (such as melamine veneer, PVC, veneer) or spraying processes.

Economy: Cost lower than solid wood and plywood, suitable for mass production.

(3) Environmental friendliness

Formaldehyde release: Environmental protection levels are E0, E1 (suitable for indoor use), E2 and above (limited to outdoor or temporary use only), and high-quality products comply with FSC/PEFC certification 29.

Sustainability: Made from waste wood, reducing resource waste by 36.

Types:

Ordinary particleboard: used for furniture substrates or building templates.

Moisture resistant particleboard: with added waterproofing agent, suitable for kitchens and bathrooms.

Decorative particleboard: surface coated with melamine film (such as ecological board), directly used for furniture 610.

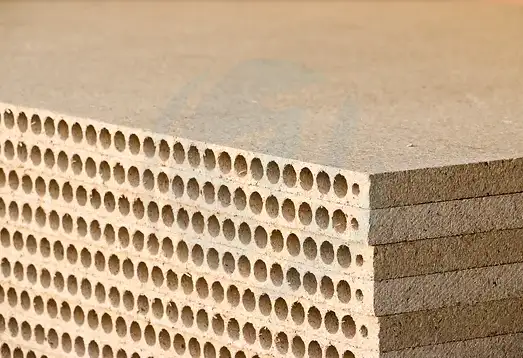

Hollow particle board: Lightweight design, used for door cores, with both sound insulation and thermal insulation properties.

Disadvantages and precautions

Durability: Weak nail grip, easy to loosen under long-term load.

Environmental risk: Poor quality products may exceed formaldehyde standards, and E0/E1 grade 98 should be selected.

Edge treatment: Edge sealing is required to avoid moisture absorption or release of harmful substances.

Application scenarios:

Furniture: Bookshelf, cabinet, conference table substrate 106.

Architecture: partition walls, ceilings, temporary formwork 9.

Packaging: Logistics pallets, cardboard box lining 3.

Contact us for free sample

- WhatsApp: +8616506393789

- plywood@yiwanjiawood.com

- Room A-1008,Building 1,Yigao Shanghai Street Liuqing Sub-district Lanshan Distrct Linyi City ,Shandong Province, China