Product Categories

Related products

| Name | Okoume Plywood |

| Size | 1220x2440mm, 1250x2500mm, 1250x3000mm, or as Customized |

| Thickness | 2.7~30mm |

| Grade | EN13986, BS1088 |

| Glue | Phenolic, E0, E1, E2 |

| Core Material | Okoume, Combi core or as request |

| Usage | Furniture, Laser Die Cutting, Toy, Loud Speaker, Construction, Flooring, etc. |

| Certification | EUTR, CARB, FSC |

What is Okoume Plywood ?

Okoume Plywood (also known as Gaboon Plywood) is a type of plywood made from African Aucoumea klaineana wood. Due to its lightweight, easy to process, and beautiful wood grain, it is widely used in shipbuilding, high-end furniture, and decorative engineering. Oguman plywood is a lightweight and high aesthetic plywood, especially suitable for the fields of ships, high-end furniture, and decoration. Its core advantages lie in light weight, easy processing, and beautiful wood grain, but waterproof models (such as BS1088 standard for marine use) need to be selected according to the usage environment. If you pursue cost-effectiveness, you can compare it to eucalyptus or birch plywood.

Feature

1. Material characteristics

Wood source: Okoume, originally from West Africa (Gabon, Cameroon, etc.), is a lightweight hardwood with a density of about 0.38-0.48 g/cm ³ (lighter than pine wood).

Texture and color:

The heartwood is light pink to light brown in color, with a delicate and straight texture resembling peach blossom heartwood.

Smooth surface, suitable for varnish or dyeing, presenting a natural high-end texture.

2. Physical properties

Characteristics of Okuman plywood comparison reference (pine plywood)

Extremely lightweight (suitable for weight reduction design), relatively heavy

Moderate strength, good flexibility, higher but more brittle

Moisture resistance is average (requiring special adhesive reinforcement), similar to (ordinary type not waterproof)

Easy to cut and polish, not prone to cracking or burrs, requiring fine processing

3. Type of glue (determines usage)

MR adhesive (moisture-proof urea formaldehyde adhesive): suitable for indoor furniture and decoration.

WBP adhesive (phenolic resin, waterproof): used for ships and outdoor structures.

BS1088 standard: High end marine plywood, seamless, all hardwood veneer, resistant to seawater corrosion.

| Okoume Plywood vs Other Plywood | |||

| Type | Okoume plywood | Birch Plywood | Pine Plywood |

| Weight | The lightest | medium | heavier |

| Moisture resistance | Medium (requires WBP adhesive) | better | general |

| Texture Aesthetics |

★★★★★

(Natural light wood grain)

|

★★★☆

(uniform but ordinary)

|

★★☆

(Multiple nodules)

|

| Price | tall | rising-falling | low |

Usage

1. Shipbuilding and yacht manufacturing (core use)

Hull structure: deck, bulkheads, hull (requiring BS1088 standard waterproof type).

Yacht interior: furniture, wall panels, counters (utilizing their lightweight and beautiful wood grain).

2. High end furniture and decoration

Curved wood furniture: chairs, curved tabletops (easy to bend).

Cabinets and decorative panels: Light colored wood grain is suitable for modern simplicity or Nordic style.

Instrument: Guitar backboard, piano components (requires carefully selected flawless sheet metal).

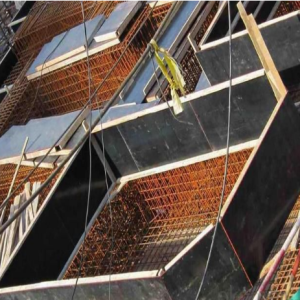

3. Architecture and Decoration

Lightweight structure: exhibition booths, temporary buildings (lightweight and easy to handle).

Decorative wall/ceiling: Natural wood grain is directly exposed without the need for skin pasting.

4. Aviation and Model Making

Model aircraft, drone framework (lightweight requirement).

Advantage and limitation

advantage

✔ Extremely lightweight: 20% -30% lighter than pine plywood, suitable for designs that require weight reduction.

✔ Processing friendly: not easy to crack, suitable for fine cutting and carving.

✔ Beautiful wood grain: can be directly coated with varnish, presenting a natural and high-end feeling.

limitation

✖ Moisture resistance is average: Ordinary models are not suitable for long-term humid environments (WBP glue or waterproof treatment is required).

✖ High price: 30% -50% more expensive than ordinary plywood (due to imported wood and high-end use).

Note

Ship/Outdoor: Choose WBP adhesive+BS1088 standard.

Indoor furniture: MR glue is sufficient, pay attention to the surface grade (A/B grade without defects).

Quality inspection:

The core layer has no gaps or patches, and the thickness of the single board is uniform.

Alternative solution:

Due to limited budget, eucalyptus plywood (with good moisture resistance but heavier weight) can be considered.